Huachen Refractory

Silica mullite refractory brick for rotary cement kiln

Phone/WhatsApp

008618939512185

Email :info@hcrefractory.com

www.silicamullitebrick.com

- Home

- About us

- Product

-

Refractory brick

Silica mullite brick

Silica mullite red brick

Magnesite alumina spinel brick

Magnesite chrome brick

Magnesite brick

Magnesite iron spinel brick

Anti spalling high alumina brick

Alkali resistant brick

Fused rebonded magnesite chrome brick

Calcium silicate insulating board

-

Monolithic Refractories

Alkali resistance castable

Wear resistance and anti skinning castable

High alumina castable

Corundum mullite castable

Steel fiber reinforced castable

Low cement castable

Self flowing castable

Refractory mortar

-

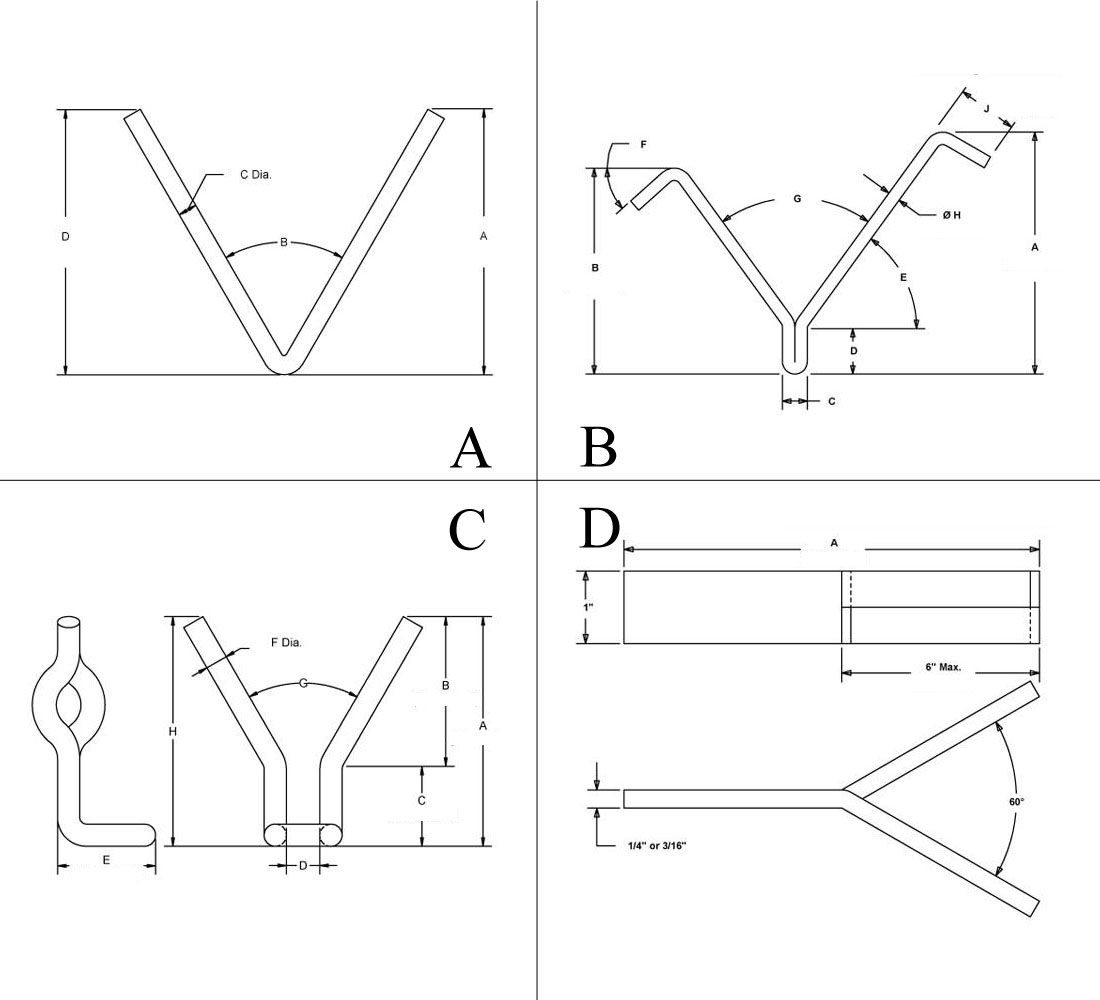

Refractory Anchor

Metal anchor

Ceramic anchor

-

Refractory brick

- News

- Support

- Enquiry

- Contact us

- Blog